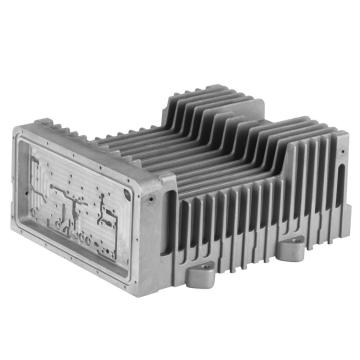

Ningbo Zhenhai Bolang Metal Product Factory werd opgericht in 2001. Bolang Centers High Precision CNC Machining Als onze kerncompetentie, is het bedrijf gespecialiseerd in het produceren van auto -onderdelen, landbouwonderdelen, machinedelen, verlichtingsonderdelen, hardwarefittingen enz. Casting, investeringsgieten, zwaartekrachtgast, het materiaal omvat aluminiumlegering zoals A380, A390, ADC12, YL102, A356, aluminium extrusie van 6000 series, zinklegering, ijzer, koper enz. De producten worden voornamelijk geëxporteerd naar landen zoals VS, Europa (Engeland, Duitsland, Italië, België enz.), Azië (Japan, Korea enz.). En het bedrijf heeft met succes IATF16949: 2016 Quality Management System Certificate, ISO14001: 2015 Environmental Management System Certificate, ISO45001: 2018 Occupational Health and Safety Management System Certificate certificaat, goedgekeurd. Het bedrijf bezit een sterke technische stroom en een hooggekwalificeerd personeelsteam, het bedrijf heeft machines met robots, trimmachines, machinecentra met hoge precisie, CNC -draaibanken, automatisch boren- en tapmachines, polijstmachines, trillingsmachines, shot blastmachines, Umtrasonisch, Umtrasonisch, Umtrasonic, Umtrasonic, Umtrasonic, Umtrasonic, Umtrasonic, Umtrasonic, Umtrasonic, Umtrasonic, Umtrasonic, Umtrasonic, Umtrasonic, Umtrasonic, Umtrasonic, Umtrasonic, Umtrasonic Reinigers enz. Het bedrijf heeft kwaliteitsinspectiefaciliteiten, zoals CMM, spectrometer, ruwheidsmeter, hardheidsmeter, het meten van projector, trekstestmachine, pneumatisch meetool, zelfontwerpende lektestmachine ET.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.